Production

We are engaged in the manufacturing of 7000 different products for 750 customers on a European-wide scale. The success of our company is based on a technologically sophisticated and individual production. We mostly use self-developed and patent-protected equipment and machinery. Our constantly high investment ratio is the basis for a modern-type and high-performance machinery.

Tool- & machinery construction

All tools required for the production of our products (punching, bending, canting etc.) are exclusively developed and manufactured by us. This way, we protect our knowhow and exclusively use it for our customers. In addition to the manufacturing, we generally maintain and repair our tools through our tool making department. We are thus able to react at short notice and to ensure the high degree of availability of our equipment.

An essential part of our product portfolio cannot be economically produced with standard machines available on the market. Our company-internal plant engineering is engaged in the preparation of innovative solutions implemented into the construction of high-performance special machines: starting with the first idea, implemented into a complete construction, up to the manufacturing, commissioning and serial production of the plant.

Development

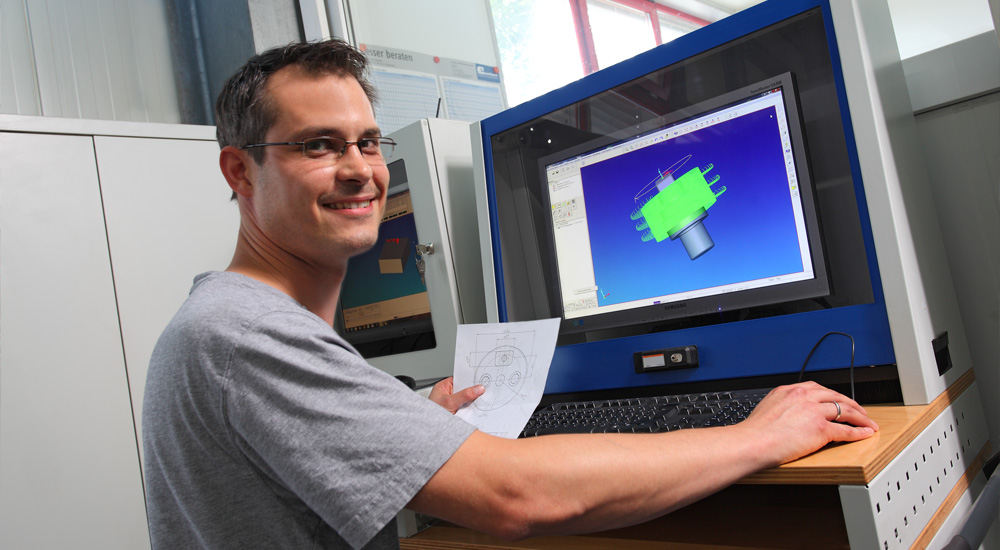

Our CAD system includes the most updated methodology of innovative design and construction generating the condition for the successful performance of our tool and plant engineering. The CAD system has also become a daily and indispensable component for our joint development projects with our customers.

Surface treatment

Surface treatment

Shot peening

Glass bead blasting

Vibratory grinding / barrel finishing

Electrolytic polishing

Pickling

Marking Systems

Laser engraving

Tampon- and laser printing

Labelling

Quality Management

An efficient quality management system is not a sure-fire success. The production of quality is daily lived by our staff members. The system is monitored through specialized staff at the best supported through the availability of most up-to-date test- and measuring equipment.

In addition to the established test- and measuring methods, we perform the following activities:

Preparation of force-path diagrams

Dynamic endurance tests

Relaxation tests

Optical image measurement

Tactile measuring of 3-D geometries

Automatic length- and diameter measuring (inline)

Permanent furnace monitoring

Metaflux method for surface crack tests

Metallurgical tests

CAQ system

Logistics

Logistics concepts based on EDI, KANBAN and call- and delivery schedules are part of the daily requirements of the market. In addition to a well-organized production, the availability of storage space capacities is an indispensable condition in this context. thema has recognized this development and has extended the logistics area by an impressive 4,000 m2 through the construction of a new ultra-modern industrial building in 2013. The total area for storage, shipment and commissioning amounts to 5,800 m2 in the meantime.

Document management

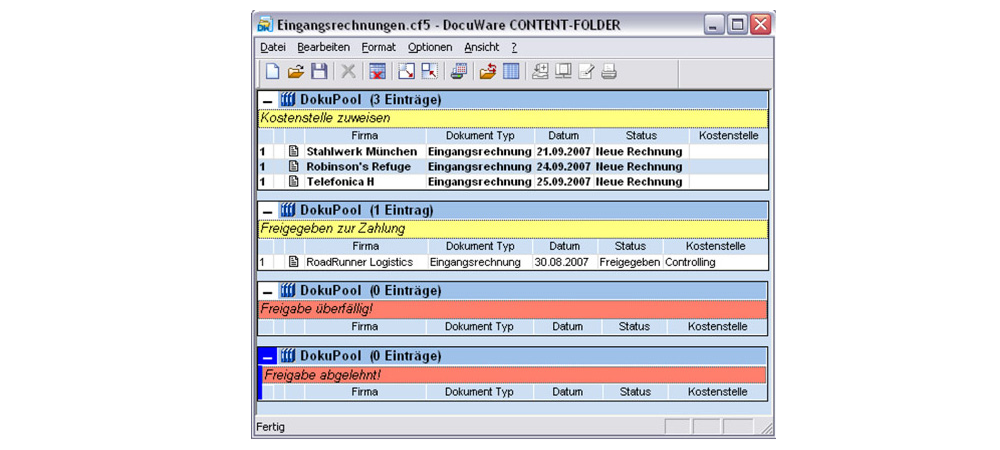

Modern document management with "Docu-Ware"

Advantages:

Lower costs

More transparency

Superior service

More orientation on the customer. Cyberspeed access to over 25,000 drawings and 1 million documents.